Description

Automatic Gravity Filling Machine

Introduction:

Gravity Filling Machine is suitable for packing with good fluidity. I uses vertical structure with constant liquid level and time which realize the precise filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjust easier.Meet with GDP standard.

Features:

1. This machine is equipped with weight feedback system. When changing the bottle size or filling volume, only press one key in the touch screen can be adjusted. Electric scale can transfer the data into the system and fine-tune have to be adjusted in the touch screen by man. While the same series machine in the market has no same function.

2. The cylinder drives the diving of the filling nozzle and matched with the variable filling speed which can reduce foaming when filling which can avoid polluting the bottles.

3. The latest designed bottle-chuck structure is adopted, convenient adjustment, and reliable structure.

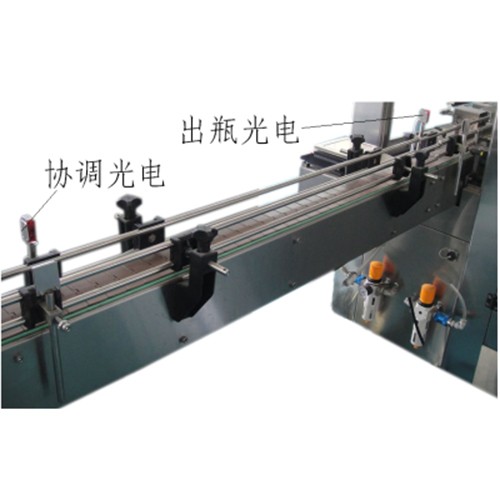

4. Optimized Bottle-in and bottle-out control modes: Normal and fast. The fast mode has no delay in bottle-in and out which improves the capacity.

5. A disassembling filter is installed in the material feeding pipe to avoid the impurities influence the filling precision and lifetime of the valves.

6. The material level sensor is used to check the level position under normal running of the machine,plus with high and low level check and alarm device. The level inspection device is made of PTFE, with perfect anti-corrosion feature.

7. A liquid holder which is controlled by an individual cylinder is installed under the filling nozzles. It can avoid the pollution to the bottle after the filling nozzles are OFF.

8. The whole machine use the frame of Stainless Steel 304 that with perfect anti-corrosion effect. The stainless steel cover and the toughened glass door prevent the dirty air during filling from polluting the environment. Meanwhile, dimensionΦ100mm exhaust outlet reserved on the top of the filling lancers which connected to the induced draught system for exhausting gas.

Notes: The connecting parts of pipe are all fast installed ,they enjoy convenient cleaning and maintenance.

Main Technical Parameters

1. Capacity : 4000-5000 bottles/hr. (500ml water as medium)

2. Applicable bottle: Diamention Φ33-100mm,Height 80-230mm

3. Volumes: 50-1000ml

4.Filling head:12

5. Precision: ±0.5%

6. Air pressure: 0.6~0.8 MPA

7. Power source: ~380V

8. Power: 1.0KW

9. External Diamention : 2000×710×2200mm (L×W×H)

10. Weight: about 480Kg

Introduction:

Gravity Filling Machine is suitable for packing with good fluidity. I uses vertical structure with constant liquid level and time which realize the precise filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjust easier.Meet with GDP standard.

Features:

1. This machine is equipped with weight feedback system. When changing the bottle size or filling volume, only press one key in the touch screen can be adjusted. Electric scale can transfer the data into the system and fine-tune have to be adjusted in the touch screen by man. While the same series machine in the market has no same function.

2. The cylinder drives the diving of the filling nozzle and matched with the variable filling speed which can reduce foaming when filling which can avoid polluting the bottles.

3. The latest designed bottle-chuck structure is adopted, convenient adjustment, and reliable structure.

4. Optimized Bottle-in and bottle-out control modes: Normal and fast. The fast mode has no delay in bottle-in and out which improves the capacity.

5. A disassembling filter is installed in the material feeding pipe to avoid the impurities influence the filling precision and lifetime of the valves.

6. The material level sensor is used to check the level position under normal running of the machine,plus with high and low level check and alarm device. The level inspection device is made of PTFE, with perfect anti-corrosion feature.

7. A liquid holder which is controlled by an individual cylinder is installed under the filling nozzles. It can avoid the pollution to the bottle after the filling nozzles are OFF.

8. The whole machine use the frame of Stainless Steel 304 that with perfect anti-corrosion effect. The stainless steel cover and the toughened glass door prevent the dirty air during filling from polluting the environment. Meanwhile, dimensionΦ100mm exhaust outlet reserved on the top of the filling lancers which connected to the induced draught system for exhausting gas.

Notes: The connecting parts of pipe are all fast installed ,they enjoy convenient cleaning and maintenance.

Main Technical Parameters

1. Capacity : 4000-5000 bottles/hr. (500ml water as medium)

2. Applicable bottle: Diamention Φ33-100mm,Height 80-230mm

3. Volumes: 50-1000ml

4.Filling head:12

5. Precision: ±0.5%

6. Air pressure: 0.6~0.8 MPA

7. Power source: ~380V

8. Power: 1.0KW

9. External Diamention : 2000×710×2200mm (L×W×H)

10. Weight: about 480Kg